Appearance

Anaerobic Digestion Module

Module Overview

The Anaerobic Digestion module in Encast provides comprehensive modelling capabilities for anaerobic digestion plants and biomass systems. This module implements a proprietary version of the US EPA's "Anaerobic Digestion Screening Tool" to estimate biogas yields and system performance ahead of implementation.

Anaerobic digestion plants convert organic waste materials into biogas through bacterial decomposition in oxygen-free environments. This biogas can then be used for electricity generation, heating, or upgraded to biomethane. The module accounts for various feedstock types, digester configurations, and operating parameters to provide accurate performance predictions.

Data Entry

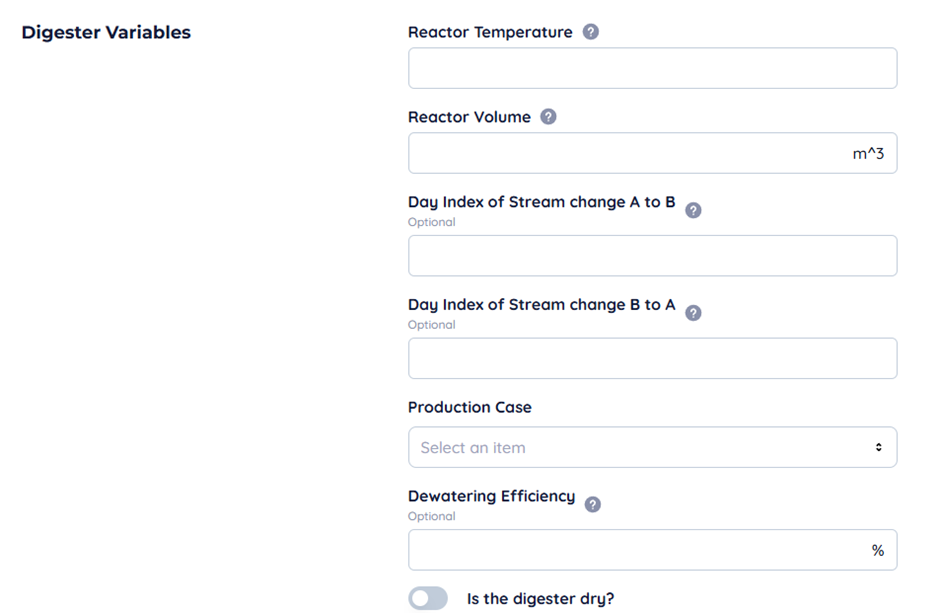

Reactor Configuration

The reactor temperature and the feedstock mix are the primary operating parameters.

Reactor Temperature: Determines the digestion regime:

- Unheated – operates between 10–20°C

- Mesophilic – operates at 30–40°C

- Thermophilic – operates at 50–60°C

The temperature regime affects gas production rates and overall system efficiency.

Performance Parameters:

- Low Percentile (25%) and High Percentile (75%) values represent the ratio between measured and modelled data

- Maximum Theoretical Gas Production representing the upper limit of biogas output

- Dewatering Efficiency affecting post-digestion digestate production

Dry Solids Content: Check the relevant flag if the digester is expected to contain between 15–40% dry solids.

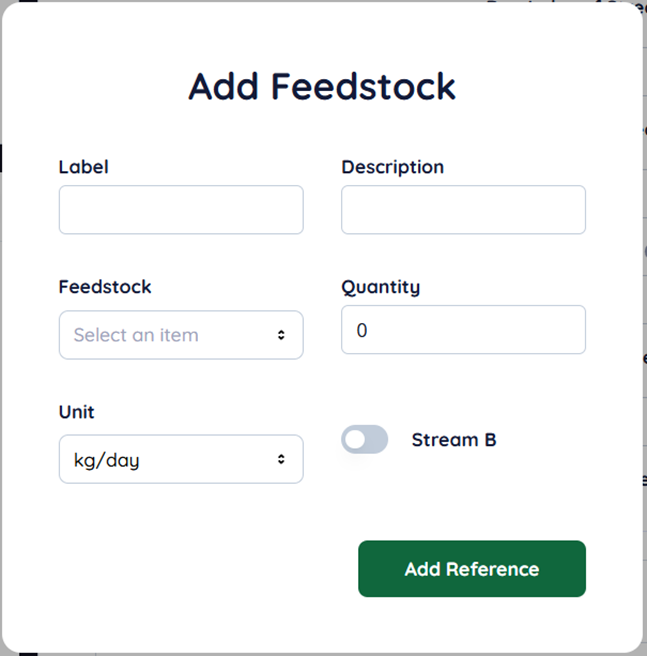

Feedstock Management

Adding feedstocks requires careful consideration of the carbon/nitrogen ratio and potential toxicity.

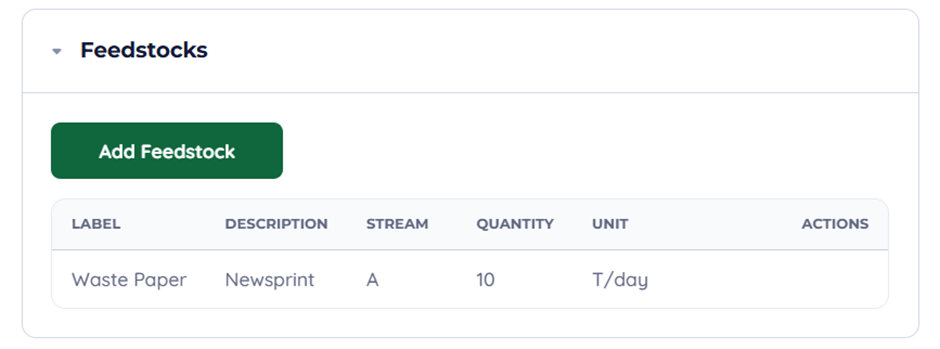

- Click "Add Feedstock" to create a new entry

- Provide a descriptive Name and Description

- Select the Feedstock Type from available options

- Enter the Quantity and select appropriate Units (e.g. metric tons per day)

- Multiple feedstocks can be added and will appear in the table of feedstocks

Important: Always click "Save Digester" before navigating away to preserve changes.

Specialisations and Use Cases

Integration with Other Systems

The biogas produced can be used by:

- Gas engines for electricity generation

- Gas turbines for combined heat and power

- Direct heating applications through gas boilers

- Upgrading to biomethane for injection into gas networks

Specialisation and Use Cases

Anaerobic digestion systems find application across diverse sectors, each presenting unique opportunities and challenges. In agricultural settings, these systems excel at processing livestock waste from dairy farms, pig operations, and poultry facilities, transforming what was once a disposal problem into a valuable energy resource. The integration extends beyond simple waste processing, as many agricultural operations use crop residues and purpose-grown energy crops like maize silage to optimise gas production and create additional revenue streams from existing land use.

The industrial and municipal sectors represent another significant application area, where anaerobic digestion addresses large-scale organic waste challenges. Food processing facilities and restaurants generate consistent waste streams that are ideal for digestion systems, while municipal wastewater treatment plants increasingly incorporate anaerobic digestion to process sewage sludge and organic fraction municipal solid waste. These applications often provide the dual benefit of waste disposal cost savings and renewable energy generation.

Commercial operations leverage anaerobic digestion for district energy systems, providing reliable heat and power to multiple buildings or industrial processes. The technology particularly suits applications requiring consistent thermal energy, as the biogas can be used directly in boilers or processed through combined heat and power systems. Large-scale installations can contribute significantly to grid-scale renewable electricity generation, especially when integrated with other renewable technologies.

Specialised configurations include co-digestion systems that combine multiple waste streams to optimise gas production through careful feedstock balancing. Advanced installations may incorporate biogas upgrading equipment to produce biomethane suitable for grid injection or vehicle fuel applications. These systems often form part of comprehensive waste-to-energy strategies, providing integrated solutions for waste management while generating multiple revenue streams through energy sales, waste gate fees, and digestate fertilizer products.

Specialized Configurations

- Co-digestion Systems: Combining multiple waste streams for optimised gas production

- Biogas Upgrading: Processing biogas to biomethane standards

- Integrated Waste Management: Part of comprehensive waste-to-energy strategies

Sensitive Parameters

The successful operation of anaerobic digestion systems depends critically on maintaining optimal biological conditions within the digesters. The feedstock mix ratios, particularly the carbon-to-nitrogen balance, fundamentally determine both gas production rates and system stability. Deviations from optimal ratios can lead to process inhibition, reduced gas yields, or complete system failure. Similarly, the hydraulic retention time and organic loading rate must be carefully managed to ensure sufficient contact time for biological processes while avoiding overloading that could destabilise the microbial community.

Temperature control represents another critical parameter, as maintaining optimal reactor temperatures requires significant energy input, particularly in cooler climates. The chosen temperature regime directly affects gas production rates and the overall energy balance of the system. pH levels must remain within narrow bands for optimal microbial activity, with monitoring and adjustment systems representing essential operational requirements.

Economic Sensitivities

- Feedstock Costs: Can vary significantly based on local availability and competition

- Gate Fees: Revenue from waste acceptance can substantially impact project economics

- Gas Utilisation Efficiency: Engine efficiency and heat recovery affect overall project returns

- Digestate Value: Revenue from processed organic fertiliser varies by local agricultural demand

Technical Risk Factors

- Feedstock Quality Consistency: Variations in waste composition affect gas production

- Temperature Control: Maintaining optimal reactor temperature is energy-intensive

- Sulfur Content: High sulfur feedstocks can cause equipment corrosion and gas cleaning requirements

- Seasonal Variations: Agricultural feedstock availability and heating demands vary throughout the year

Regulatory and Environmental

- Environmental Permits: Waste handling and emission regulations

- Planning Consent: Odour management and community acceptance

- Waste Classification: Regulatory requirements for different waste types

- Digestate Quality Standards: Meeting organic fertiliser certification requirements