Appearance

Gas Engine Module

Module Overview

The Gas Engine module in Encast provides comprehensive modelling capabilities for reciprocating internal combustion engines designed to operate on gaseous fuels, particularly biogas from anaerobic digestion systems. This module specialises in engines that utilise various biogas compositions, from pure biogas (BG0) to biogas blends with natural gas or air, supporting applications from waste-to-energy facilities to combined heat and power systems integrated with organic waste processing.

Gas engines represent a critical technology for converting biogas into useful electrical and thermal energy, enabling the economic utilisation of organic waste streams while providing reliable power generation. Unlike diesel engines, gas engines are specifically designed to handle the unique characteristics of biogas, including variable methane content, trace contaminants, and lower heating values that require specialised combustion systems and fuel management approaches.

The integration with Encast's anaerobic digestion module creates a complete waste-to-energy modelling capability, allowing users to model the entire process from organic feedstock input through biogas production to final energy output. This comprehensive approach enables accurate assessment of integrated waste-to-energy projects that are increasingly important for industrial operations seeking to achieve energy independence while addressing organic waste management challenges.

Data Entry

Installation

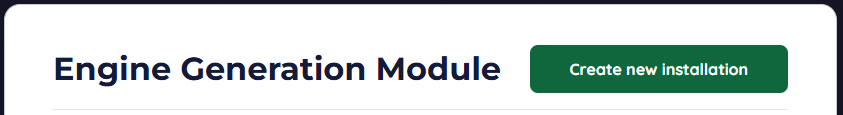

Engines are added by selecting "Create new installation".

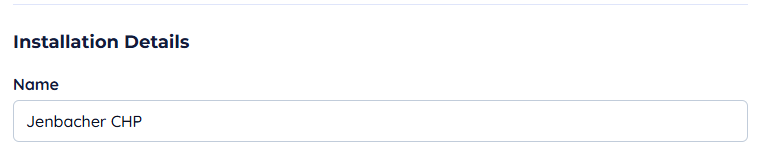

Installation Details

Name: Identifier for the installation.

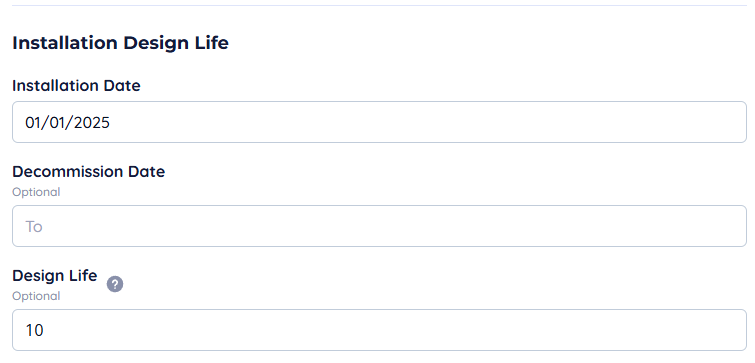

Installation Design Life

Defines the operational period of the engine.

- Installation Date: Date installation is complete.

- Decommission date (Optional): Date after which the installation is unavailable.

- Design Life (Optional): Number of years from installation date the installation will be available.

An installation date is required. If neither decommission date nor design life are present, the engine is considered installed until the end of the simulation.

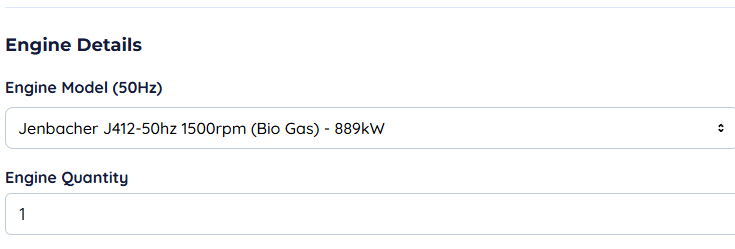

Engine Details

Engine Model: Select the engine from the drop-down menu. Engine Quantity: The number of engines. Engines are treated as being in parallel, load distributed equally, maintenance applies to all at once.

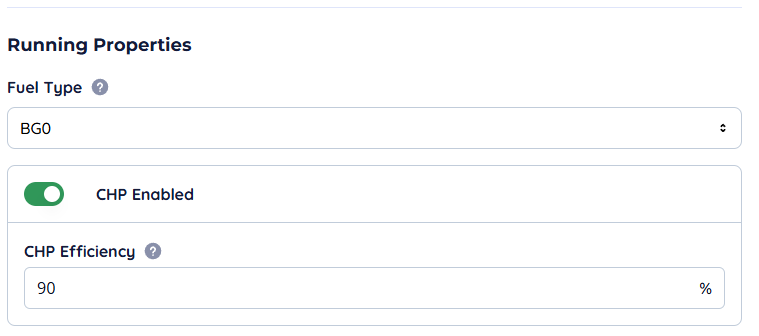

Running Properties

Fuel Type: BG0 (Bio-Gas 100%), BG20 (Bio-Gas 80%), BG40 (Bio-Gas 60%), BG50 (Bio-Gas 50%). CHP Efficiency: Total efficiency of the CHP system (heat potential heat recovered). Usually over 90%.

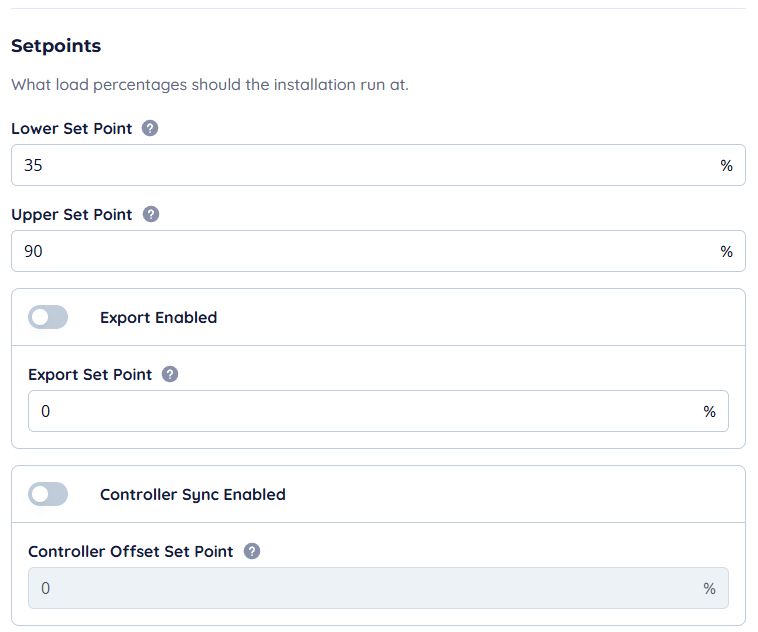

Set Points

- Lower Set Point: Engines stop below this percentage of total capacity.

- Upper Set Point: Engines stop above this percentage of total capacity.

- Export Set Point (Optional): If enabled, installation never drops below this set point; excess is exported.

- Controller Sync Offset Set Point (Optional): Required if "Controller Sync" is enabled, for percentage of total output to energise alternators.

Operational Times and Maintenance

- Operational Times can be used to define the times when an installation is active.

- Maintenance is used to create shutdown periods to maintain assets or automatic costs based on the amount of hours an installation has run.

These are explained in more detail in the Operational Times and Maintenance Section after Modules.

Specialisations and Use Cases

Integration with Anaerobic Digestion Systems

Gas engines form the cornerstone of integrated waste-to-energy systems by:

- Converting biogas from anaerobic digesters into electrical power and useful thermal energy

- Enabling complete utilisation of organic waste streams through integrated processing chains

- Providing baseload renewable energy generation from consistent biogas production

- Supporting grid stability through dispatchable renewable energy that complements variable solar and wind generation

Agricultural and Food Processing Applications

Agricultural operations represent the largest application sector for gas engine systems, leveraging the symbiotic relationship between organic waste production and energy demand. Dairy farms utilise gas engines to convert livestock waste into electricity and heat for barn operations, milk cooling, and hot water sanitisation. The integration creates a closed-loop system where waste becomes a valuable energy resource while simultaneously addressing environmental compliance requirements for organic waste management.

Food processing facilities, including meat processing plants, breweries, and vegetable processing operations, generate significant organic waste streams ideal for anaerobic digestion and subsequent gas engine utilisation. These facilities benefit from the dual value proposition of waste disposal cost reduction and on-site renewable energy generation. The consistent thermal loads required for processing operations align well with the continuous heat output from gas engine CHP systems, creating highly efficient overall energy utilisation.

Poultry operations and pig farms particularly benefit from gas engine installations due to the high methane potential of their waste streams and consistent energy demands for ventilation, heating, and feed processing. The rapid payback periods achievable in these applications make them attractive for agricultural businesses seeking to improve environmental performance while reducing energy costs.

Municipal and Industrial Waste Processing

Wastewater treatment plants increasingly deploy gas engine systems to utilise biogas produced from sewage sludge digestion. These installations provide energy security for critical infrastructure while reducing operational costs and environmental impact. The biogas utilisation transforms waste treatment from an energy-intensive process into a potential net energy producer, fundamentally changing the economics of municipal waste management.

Industrial applications include organic waste processing facilities, landfill gas utilisation projects, and integrated waste management systems that combine multiple organic waste streams. These systems often incorporate sophisticated gas cleaning and conditioning equipment to handle trace contaminants and ensure reliable engine operation across variable gas composition conditions.

Commercial and Institutional Applications

Large-scale commercial facilities, including shopping centres, hotels, and institutional buildings, increasingly explore biogas utilisation from food waste and organic material processing. Educational institutions and healthcare facilities benefit from the reliable baseload power generation while demonstrating environmental leadership through visible renewable energy systems.

District energy systems incorporating gas engines provide both electrical power and thermal energy for multiple buildings or industrial processes, maximising the economic and environmental benefits of biogas utilisation. These systems often feature thermal storage and sophisticated control systems to optimise energy delivery across varying demand patterns.

Specialised Configurations

- Multi-Fuel Systems: Engines capable of operating on varying biogas compositions or supplemented with natural gas

- Advanced Gas Cleaning: Integration with gas purification systems for enhanced engine reliability

- Thermal Integration: Sophisticated heat recovery systems for industrial process integration

- Grid Services: Participation in demand response and ancillary service markets

Sensitive Parameters

Gas engine performance and reliability depend critically on biogas composition and quality parameters that can vary significantly over time. Methane content represents the primary factor affecting engine power output and efficiency, with typical biogas containing 50-70% methane compared to natural gas at 95%+ methane content. Variations in methane content directly impact heating value and require engine management systems capable of adjusting fuel-air ratios to maintain optimal combustion conditions.

Hydrogen sulfide content represents one of the most significant operational challenges, as this corrosive compound can cause rapid degradation of engine components, fuel systems, and exhaust systems. Even relatively low concentrations of H2S, typically measured in parts per million, can necessitate expensive gas cleaning equipment and frequent maintenance of engine components. The relationship between H2S content and maintenance costs is non-linear, with concentrations above 1000 ppm often requiring comprehensive gas desulfurisation systems.

Siloxane compounds, primarily from personal care products in municipal waste streams, can cause severe engine damage through silicon oxide formation during combustion. These compounds are particularly problematic in landfill gas and sewage gas applications, requiring specialised removal systems and careful monitoring to prevent catastrophic engine failure. The presence of siloxanes often determines the feasibility and economics of gas engine projects in municipal applications.

Temperature and pressure stability of the biogas supply significantly affect engine performance and operational reliability. Gas engines require consistent fuel pressure and temperature for optimal operation, making storage systems and gas conditioning equipment essential components of successful installations. Variations in digester performance directly translate to engine operational challenges, creating interdependencies that must be carefully managed through system design and operational procedures.

Economic Sensitivities

- Biogas Production Consistency: Variations in feedstock quality and digester performance affect fuel availability

- Gas Cleaning Requirements: H2S and siloxane removal systems represent significant capital and operational costs

- Heat Utilisation Efficiency: Economic viability depends heavily on effective thermal energy utilisation

- Maintenance Cost Escalation: Biogas contaminants increase maintenance frequency and component replacement costs

Technical Risk Factors

- Gas Composition Variability: Changing methane content affects power output and engine management requirements

- Corrosive Compounds: H2S and other contaminants accelerate component wear and increase maintenance costs

- Fuel System Complexity: Gas conditioning, pressure regulation, and safety systems add operational complexity

- Seasonal Performance: Digester temperature variations affect biogas production and composition

Regulatory and Environmental Considerations

- Emission Standards: NOx and CO limits may require sophisticated exhaust aftertreatment systems

- Gas Safety Regulations: Specialised requirements for combustible gas handling and storage systems

- Waste Management Compliance: Integration with organic waste processing regulations and permits

- Grid Connection Standards: Utility interconnection requirements for distributed generation systems

- Planning and Environmental Permits: Coordination between waste processing and power generation approvals