Appearance

Gas Turbine Module

Module Overview

The Gas Turbine module in Encast provides sophisticated modelling capabilities for gas turbine power generation systems, incorporating the complex operational characteristics that distinguish these machines from other generation technologies. Gas turbines operate within Encast's modular stack framework, typically positioned after renewable energy sources and battery storage but before heat storage systems, allowing them to provide flexible backup power and combined heat and power services.

Gas turbines are high-performance thermal machines that require extensive parametrisation to model accurately, with approaching two dozen critical parameters governing their startup, ramping, operational constraints, and shutdown behaviours. Unlike simpler generation modules, gas turbines must account for significant thermal mass effects, complex efficiency curves that vary with ambient conditions, and sophisticated control systems that manage ramping rates and minimum operating constraints.

The module's integration with Encast's operational criteria and event condition systems allows for sophisticated control modelling, enabling users to simulate complex operational strategies such as load following, peak shaving, and grid stabilisation services. This capability is essential for accurately modelling gas turbines in systems with high renewable energy penetration, where their rapid start capability and operational flexibility provide critical grid support services.

Data Entry

Gas turbines have complex ramping startup and shutdown requirements and approaching two dozen parameters to enable proper modelling in Encast.

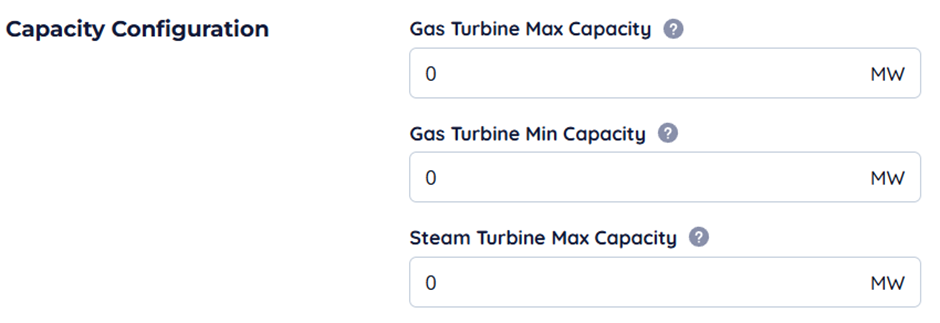

Capacity Configuration

Define the capacity of the turbine in MW. Below the minimum capacity of the gas turbine, it will shut down if already running or not start if offline.

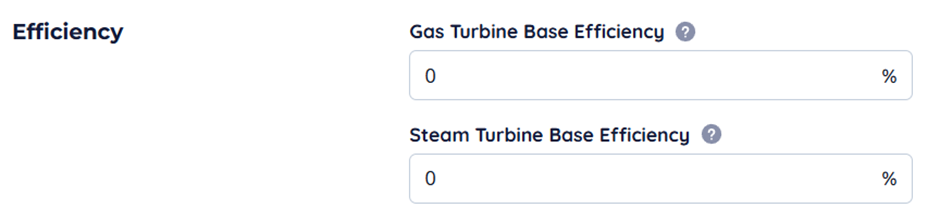

Efficiency Configuration

Define the efficiencies for both the gas turbine and steam turbine components. Note that these are separate from each other—do not use the combined efficiency of a turbine for this data. For example, if a gas turbine has an efficiency of 38% operating in a simple cycle, but the datasheet gives a nominal combined cycle of 55%, the steam turbine base efficiency must be calculated separately.

The combined cycle efficiency formula is:

Where

Rearranging for

Using the example values:

The efficiencies of both turbines vary across their load bands and must be calculated separately. CCGT plants can have wildly different efficiencies for heat recovery even with the same gas turbine.

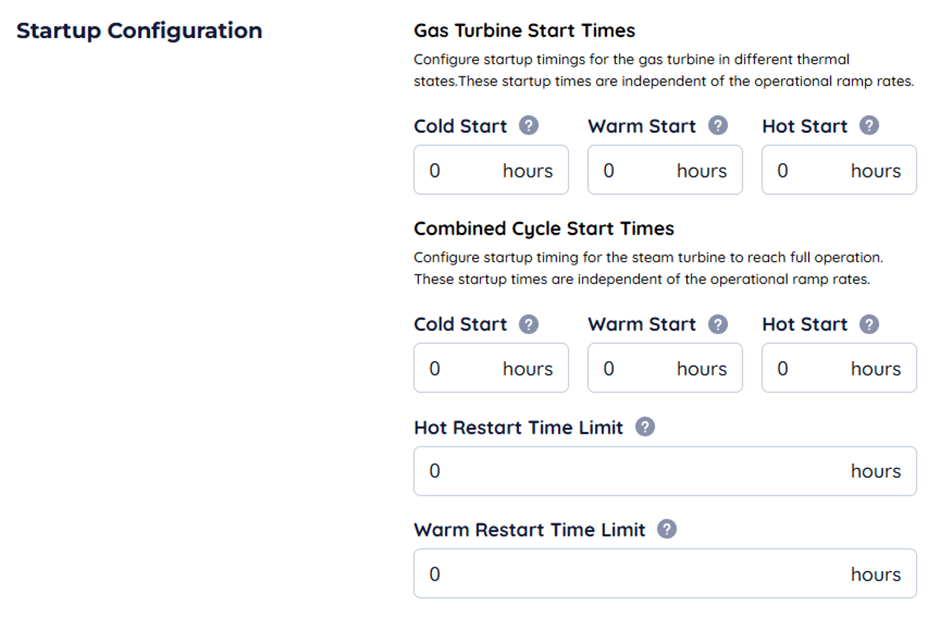

Startup Configuration

Plant design affects start times and restart times. Some operators prioritise the longevity of the turbine, requiring longer shutdowns to reduce stress on parts and prevent excessive plant starts.

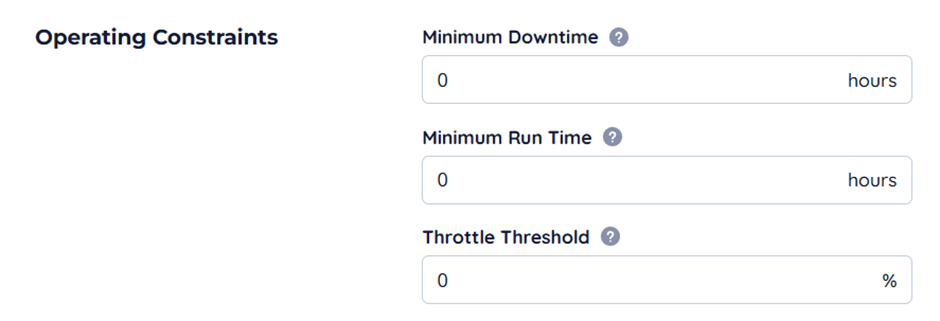

Operating Constraints

Minimum Downtime: The amount of time the turbine must remain off after being shut down.

Minimum Runtime: How long the generator must remain running once started.

Throttle Threshold: Operates similarly to a lower setpoint on a reciprocating engine generator, if this is above the minimum load of the gas turbine.

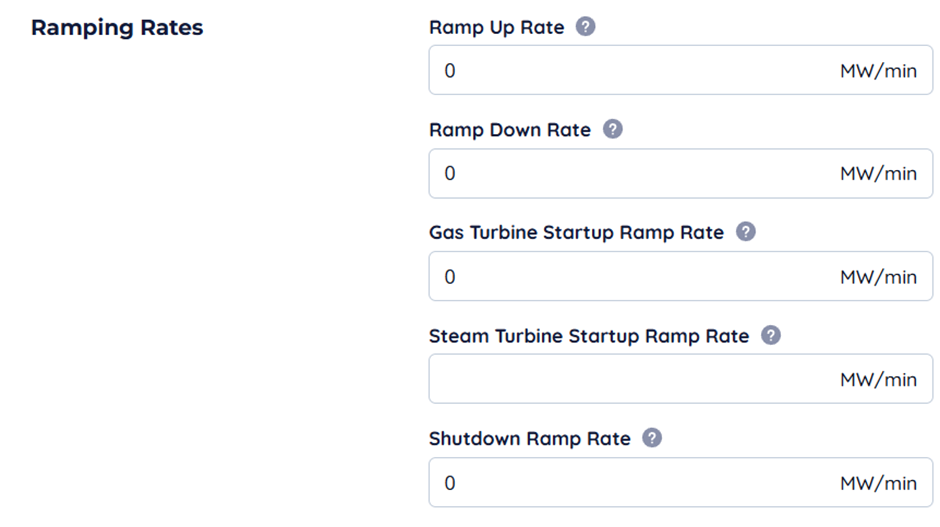

Ramping Rates

Due to rotating mass, unlike most other modules, turbines require ramp-up and ramp-down time. For aeroderivative turbines this might not be significant as they are designed to ramp quickly without hot lockout periods. More performant turbines require careful ramping control.

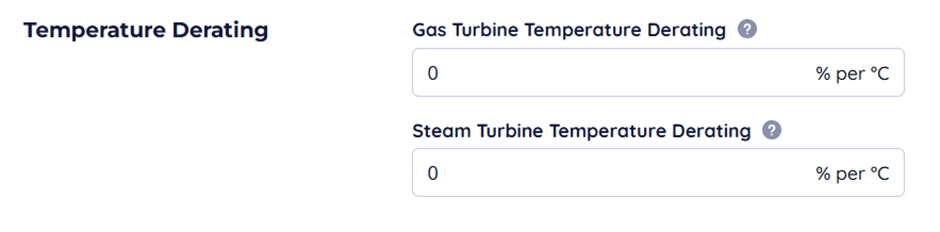

Temperature Derating

Turbines become less efficient in warmer weather. The standard reference temperature is 15°C. Temperature derating factors account for the impact of ambient conditions on turbine performance.

Specialisations and Use Cases

Gas turbines serve diverse applications across industrial, commercial, and utility sectors, each leveraging the technology's unique characteristics. Industrial applications particularly benefit from the high-quality waste heat produced by gas turbines, making them ideal for facilities requiring both electricity and process steam or hot water. Manufacturing plants, chemical facilities, and food processing operations frequently deploy gas turbines in combined heat and power configurations to maximise overall energy efficiency and reduce operational costs.

District energy systems represent another significant application area, where gas turbines provide reliable electricity generation while supplying thermal energy for space heating, cooling through absorption chillers, and domestic hot water production. The rapid start capability of gas turbines makes them particularly valuable for providing backup power and grid stability services, especially in systems with high renewable energy penetration where quick response to load changes is essential.

Utility-scale applications leverage gas turbines for peaking power generation, load following, and grid stabilisation services. Modern gas turbines can achieve rapid startup times and excellent part-load efficiency, making them ideal for balancing variable renewable energy sources. Advanced installations incorporate sophisticated control systems that optimise performance across varying load conditions while maintaining compliance with environmental regulations.

Specialised applications include offshore platforms where the compact design and high power density of gas turbines provide essential advantages over other generation technologies. Landfill gas and biogas applications use specially configured turbines designed to handle lower heating value fuels while maintaining reliable operation. Emergency and standby power applications benefit from the quick-start capability and high reliability of gas turbines, providing critical backup power for hospitals, data centres, and essential facilities.

Sensitive Parameters

The performance and economics of gas turbine systems depend critically on several interconnected parameters that require careful consideration during design and operation. Ambient temperature represents perhaps the most significant operational variable, with turbine output typically decreasing by 0.5–0.7% for each degree Celsius increase in ambient temperature. This temperature sensitivity directly impacts both power output and thermal efficiency, making site choice and seasonal performance variations crucial factors in project economics.

Fuel quality and composition significantly influence turbine performance, maintenance requirements, and operational costs. Natural gas with consistent heating value and low contaminant levels provides optimal performance, while alternative fuels such as biogas or hydrogen blends may require specialised combustion systems and modified operational procedures. Fuel supply reliability and price volatility represent major economic risk factors that can substantially impact project viability over the operational lifetime.

Load factor and operational cycling patterns critically affect both performance and maintenance costs. Gas turbines achieve optimal efficiency at or near rated capacity, with significant efficiency penalties at low-load conditions. Frequent cycling between startup and shutdown increases maintenance requirements and reduces component life, while baseload operation maximises efficiency but may not align with electricity market demands or thermal load requirements.

Maintenance scheduling and parts availability represent ongoing operational challenges that can significantly impact system reliability and costs. Gas turbines require specialised maintenance expertise and high-value replacement parts, with major overhauls typically required every 25,000–50,000 operating hours depending on the specific model and operational profile. Environmental compliance requirements, particularly regarding emission limits and noise restrictions, may require additional equipment such as selective catalytic reduction systems or acoustic enclosures that increase both capital and operational costs.

Grid connection requirements and electrical system integration complexity can introduce significant technical and economic challenges. Power quality standards, protection system coordination, and grid code compliance requirements vary significantly by location and system size. Interconnection studies may reveal necessary grid upgrades that substantially increase project costs, while electrical system design must accommodate the specific characteristics of gas turbine generators to ensure reliable and safe operation.