Appearance

Cooler Module

Module Overview

The Cooler module in Encast provides comprehensive modelling capabilities for electric cooling systems designed to provide space conditioning, process cooling, and refrigeration across diverse applications from residential air conditioning to large-scale industrial cooling systems. This module enables accurate simulation of various cooling technologies, including air-cooled chillers, water-cooled systems, and direct expansion units with sophisticated performance modelling based on ambient conditions and load requirements.

Cooling systems represent critical infrastructure for maintaining comfortable indoor environments, preserving products, and supporting industrial processes that require precise temperature control. The module accounts for various cooling technologies, efficiency characteristics, and operational constraints to provide accurate performance predictions and economic analysis throughout the system's operational life.

Modern cooling technology encompasses high-efficiency systems with advanced refrigeration cycles, variable-speed compressors, and intelligent control systems that optimise performance across varying load and ambient conditions. The diversity of cooling applications, from residential comfort cooling to data centre precision cooling, makes this module essential for comprehensive energy system analysis across all building types and industrial applications.

Data Entry

Installation

Coolers are added by selecting "Create new cooler installation".

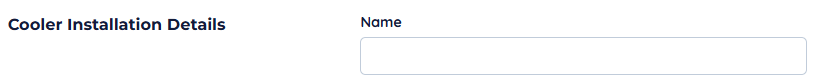

Installation Details

Name: Identifier for the installation.

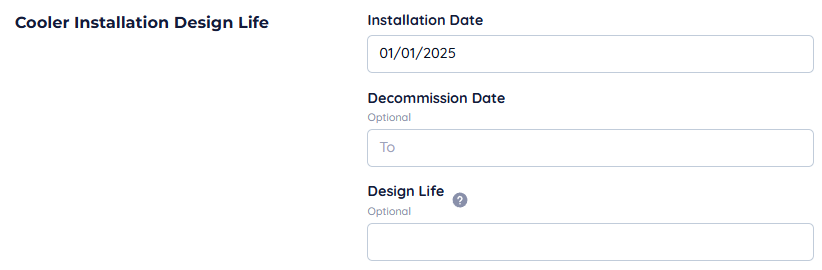

Installation Design Life

Defines the operational period of the cooler.

- Installation Date: Date installation is complete.

- Decommission date (Optional): Date after which the installation is unavailable.

- Design Life (Optional): Number of years from installation date the installation will be available.

An installation date is required. If neither decommission date nor design life are present, the cooler is considered installed until the end of the simulation.

Cooler Performance Parameters

Capacity: Maximum cooling capacity in kW at rated conditions. EER: Energy Efficiency Ratio - ratio of cooling capacity to electrical power input at full load conditions. ESEER: European Seasonal Energy Efficiency Ratio - weighted efficiency across part-load conditions representing typical seasonal operation.

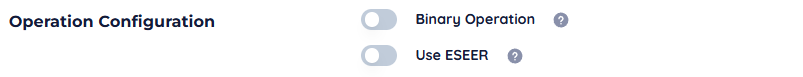

Operation Configuration

Binary Operation: Forces the cooler to operate at full capacity when on, or be completely off, instead of the default behaviour where output modulates to match cooling demand. Use ESEER: When enabled, uses the ESEER value for performance calculations instead of the fixed EER, providing more accurate seasonal performance modelling.

Operational Times and Maintenance

- Operational Times can be used to define the times when an installation is active.

- Maintenance is used to create shutdown periods to maintain assets or automatic costs based on the number of hours an installation has run.

These are explained in more detail in the Operational Times and Maintenance Section after Modules.

Specialisations and Use Cases

Integration with Other Systems

Coolers complement comprehensive HVAC systems and support building energy management strategies by:

- Providing reliable cooling capacity during peak demand periods and high ambient temperatures

- Supporting renewable energy systems through thermal storage integration and demand response capabilities

- Enabling district cooling networks with centralised cooling generation and distribution

- Integrating with building management systems for optimised energy consumption and comfort control

Residential and Commercial Applications

Residential cooling installations serve critical comfort and health functions across diverse climates and building configurations. Modern high-efficiency air conditioning systems utilise variable-speed compressors and advanced refrigeration cycles to provide precise temperature and humidity control while minimising energy consumption. Heat pump systems provide both heating and cooling capabilities, offering year-round climate control with superior energy efficiency compared to separate heating and cooling systems.

Commercial buildings leverage cooling systems for occupant comfort, equipment protection, and specialised environmental requirements. Large commercial installations often incorporate multiple chiller configurations that provide operational redundancy and improved part-load efficiency through staged operation and load distribution. The integration with building management systems enables sophisticated control strategies that optimise energy consumption based on occupancy schedules, outdoor conditions, and utility rate structures.

Office buildings and retail facilities require cooling systems capable of handling significant internal heat gains from lighting, equipment, and occupancy while maintaining comfortable conditions throughout varying daily and seasonal patterns. These installations often feature economiser systems that utilise outdoor air for free cooling when ambient conditions are favorable, significantly reducing mechanical cooling energy consumption.

Healthcare facilities and educational institutions represent demanding applications where cooling systems provide critical environmental control for patient care, laboratory operations, and occupant comfort. These installations often incorporate backup cooling capacity and sophisticated air filtration systems to ensure continuous operation and indoor air quality compliance.

Industrial and Process Cooling Applications

Industrial facilities utilise cooling systems for process temperature control, equipment protection, and worker comfort across diverse manufacturing operations. Data centres represent one of the most demanding cooling applications, requiring precise temperature and humidity control with extremely high reliability to protect valuable computing equipment and maintain operational availability.

Manufacturing processes often require cooling systems for product quality control, equipment protection, and process optimisation. Food processing facilities depend on refrigeration systems for product preservation, safety compliance, and process cooling requirements. Pharmaceutical and chemical manufacturing operations utilise cooling systems for reaction temperature control, product storage, and environmental compliance.

Server rooms and telecommunications facilities require cooling systems with high reliability and precise control capabilities to protect electronic equipment and maintain service availability. These installations often incorporate redundant cooling capacity and sophisticated monitoring systems to ensure continuous operation even during equipment failures.

Specialized Configurations

- Thermal Storage Integration: Coupling cooling systems with chilled water or ice storage for demand management

- Heat Recovery Applications: Utilising waste heat from cooling systems for heating and hot water applications

- District Cooling Systems: Centralised cooling generation with chilled water distribution networks

- Hybrid Systems: Combining multiple cooling technologies for optimised performance and reliability

Sensitive Parameters

Cooling system performance depends critically on ambient temperature conditions that directly affect both cooling capacity and energy efficiency. Air-cooled systems experience significant performance degradation at high outdoor temperatures when cooling demand is typically highest. The relationship between ambient temperature and system performance is non-linear, with efficiency dropping rapidly as outdoor temperatures exceed design conditions.

Humidity levels significantly affect cooling system performance and energy consumption, particularly in applications requiring precise humidity control. High humidity conditions increase the latent cooling load while reducing the sensible cooling capacity of the equipment. Dehumidification requirements can substantially increase energy consumption and affect overall system efficiency.

Load factor and cycling patterns critically affect both energy efficiency and equipment longevity. Cooling systems typically achieve highest efficiency at part-load conditions when properly sized and controlled. However, systems that are significantly oversized for the actual cooling load will experience frequent cycling, reduced efficiency, and increased maintenance requirements.

Refrigerant charge levels and system cleanliness directly impact cooling performance and reliability. Refrigerant leaks, dirty condenser coils, or restricted airflow can cause substantial performance degradation and increased energy consumption. Regular maintenance and monitoring are essential for maintaining design performance throughout the system's operational life.

Economic Sensitivities

- Electricity Rate Structures: Time-of-use rates and demand charges significantly impact cooling system operational costs

- Efficiency Degradation: Fouling, refrigerant leaks, and component wear reduce efficiency over time

- Maintenance Cost Escalation: Specialised refrigeration service requirements affect long-term operational costs

- Peak Demand Management: Cooling loads often drive building peak electrical demand and associated utility charges

Technical Risk Factors

- Ambient Temperature Dependence: Performance varies significantly with outdoor conditions during peak demand periods

- Refrigerant Regulations: Phase-out of certain refrigerants may require system replacement or conversion

- Power Quality Sensitivity: Voltage fluctuations and harmonics can affect compressor operation and longevity

- System Integration Complexity: Poor design of chilled water or refrigerant distribution systems reduces efficiency

Regulatory and Environmental Considerations

- Refrigerant Regulations: Global warming potential limits and phase-out schedules for refrigerants

- Energy Efficiency Standards: Minimum efficiency requirements for new installations and replacements

- Noise Regulations: Sound level limits for outdoor equipment in residential and commercial areas

- Environmental Permits: Refrigerant handling and disposal requirements for large systems

Operational Challenges

- Part-Load Performance: System efficiency and capacity modulation capabilities across varying loads

- Seasonal Performance Variation: ESEER provides more accurate representation than fixed EER ratings

- Maintenance Access: Outdoor equipment requires weather protection and accessible service areas

- Load Matching: Proper sizing critical for efficiency and comfort while avoiding short cycling

Performance Optimisation

Efficiency Improvements

Modern cooling installations benefit from several efficiency enhancement strategies. Variable-speed drive technology enables precise capacity modulation and improved part-load efficiency by matching cooling output to demand. These systems avoid the cycling losses associated with fixed-speed equipment while providing better temperature and humidity control.

Economiser systems utilise favorable outdoor air conditions for free cooling, significantly reducing mechanical cooling energy consumption during suitable weather conditions. Air-side and water-side economisers can provide substantial energy savings in appropriate climates while extending equipment life through reduced operating hours.

Advanced control systems optimise cooling system operation based on occupancy schedules, outdoor conditions, and utility rate structures. These systems can implement demand-limiting strategies, optimal start/stop scheduling, and equipment rotation to maximise efficiency while minimising operating costs.

Integration Strategies

Thermal storage systems enable cooling equipment to operate during off-peak utility rate periods while providing cooling capacity during peak demand periods. Ice storage and chilled water storage systems can significantly reduce electrical demand charges while improving overall system efficiency through optimised equipment operation.

Heat recovery systems capture waste heat from cooling operations for heating and hot water applications, improving overall energy utilisation. Heat recovery chillers can simultaneously provide cooling and heating, particularly valuable in applications with year-round heating requirements.

Building management system integration enables comprehensive energy optimisation through coordinated control of cooling, ventilation, and lighting systems. These integrated approaches can achieve significant energy savings through reduced simultaneous heating and cooling, optimised ventilation rates, and load-responsive equipment operation.

Conclusion

The Cooler module provides essential capabilities for modelling cooling systems across diverse applications from residential comfort cooling to large-scale industrial process requirements. Understanding the critical parameters affecting cooling system performance, efficiency, and reliability enables informed decision-making about cooling system investments and operational strategies.

Successful cooling installations require careful attention to proper sizing, efficiency optimisation, and control strategies that balance comfort requirements with energy consumption. The module's comprehensive modelling capabilities enable accurate assessment of different cooling technologies and configurations for specific application requirements.

Regular monitoring of performance parameters, proactive maintenance scheduling, and continuous optimisation of control strategies ensure cooling systems deliver reliable, efficient cooling throughout their operational life while minimising environmental impact and operational costs.