Appearance

Heat Pump Module

Module Overview

The Heat Pump module in Encast provides comprehensive modelling capabilities for electric heat pump systems designed to extract thermal energy from ambient sources and deliver it for space heating, domestic hot water production, and industrial process applications. This module enables accurate simulation of various heat pump technologies from residential air-source units to large-scale industrial heat pump installations across diverse operational configurations.

Heat pumps represent one of the most energy-efficient heating technologies available, utilising the refrigeration cycle to extract heat from air, ground, or water sources and concentrate it for useful heating applications. The module accounts for various heat pump types, coefficient of performance characteristics, and operational constraints to provide accurate performance predictions and economic analysis throughout the system's operational life.

Modern heat pump technology encompasses high-efficiency systems with variable-speed compressors, advanced refrigerant cycles, and intelligent defrost systems that maintain performance across varying ambient conditions. The ability to provide both heating and cooling, combined with coefficients of performance exceeding 300%, makes heat pump systems essential components in comprehensive energy strategies across residential, commercial, and industrial applications.

Data Entry

Installation

Heat pumps are added by selecting "Create new heat pump installation".

Installation Details

Name: Identifier for the installation.

Installation Design Life

Defines the operational period of the heat pump.

- Installation Date: Date installation is complete.

- Decommission date (Optional): Date after which the installation is unavailable.

- Design Life (Optional): Number of years from installation date the installation will be available.

An installation date is required. If neither decommission date nor design life are present, the heat pump is considered installed until the end of the simulation.

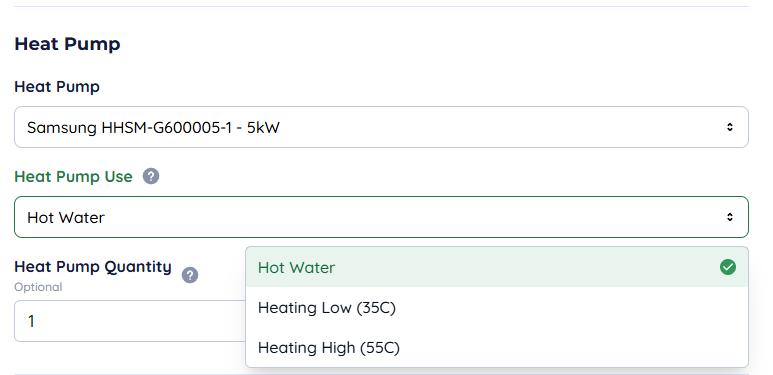

Heat Pump Parameters

- Heat Pump Model: Select the heat pump model from the drop-down menu.

- Heat Pump Use: Hot Water (45℃ target), Heating Low (35℃, for underfloor heating), Heating High (55℃, for radiators/anti-Legionella).

- Heat Pump Quantity: The number of units in the installation of the selected model.

Operation Configuration

Minimum Operating Temperature: Lowest ambient temperature for heat pump operation. Defrost Control: Automatic defrost cycle management for air-source units. Modulation Range: Capacity modulation capabilities as percentage of rated output.

Operational Times and Maintenance

- Operational Times can be used to define the times when an installation is active.

- Maintenance is used to create shutdown periods to maintain assets or automatic costs based on the number of hours an installation has run.

These are explained in more detail in the Operational Times and Maintenance Section after Modules.

Specialisations and Use Cases

Integration with Other Systems

Heat pumps complement renewable energy systems and support comprehensive energy strategies by:

- Providing high-efficiency heating using renewable electricity from solar and wind systems

- Supporting grid stability through demand response capabilities and thermal storage integration

- Enabling electrification of heating to reduce dependence on fossil fuel combustion

- Integrating with building management systems for optimised energy consumption and comfort control

Residential and Commercial Applications

Residential heat pump installations represent the fastest-growing heating technology segment, offering superior energy efficiency compared to conventional heating systems. Air-source heat pumps provide year-round heating and cooling capabilities with coefficient of performance values typically ranging from 2.5 to 4.5, depending on ambient conditions and system design. Ground-source heat pumps achieve even higher efficiencies by utilising stable ground temperatures, though requiring higher initial installation costs.

Modern residential heat pumps incorporate advanced features including variable-speed compressors, intelligent defrost systems, and low-ambient temperature operation capabilities that maintain heating capacity even at outdoor temperatures below -20°C. Integration with smart home systems enables optimised operation based on occupancy patterns, utility rate structures, and weather forecasts.

Commercial buildings leverage heat pump systems for space conditioning, domestic hot water, and specialised process applications. Large commercial installations often incorporate multiple heat pump configurations that provide operational redundancy and improved part-load efficiency through staged operation. Variable refrigerant flow systems enable precise temperature control across different building zones while maximising energy efficiency.

Healthcare facilities and hotels represent demanding applications where heat pumps provide critical domestic hot water requirements with strict temperature control and anti-Legionella protocols. These installations often incorporate thermal storage systems and backup heating capacity to ensure continuous availability of hot water services while maximising heat pump efficiency.

Industrial Process Applications

Industrial facilities increasingly utilise heat pumps for process heating requirements, particularly for applications below 100°C where heat pumps can achieve exceptional efficiency compared to direct electric heating or steam systems. Food processing operations leverage heat pumps for pasteurisation, drying, and cleaning processes while achieving significant energy savings and reduced environmental impact.

Pharmaceutical and chemical manufacturing facilities utilise heat pumps for precise temperature control in production processes, laboratory applications, and facility conditioning. The ability to provide both heating and cooling from a single system offers operational flexibility while reducing equipment complexity and maintenance requirements.

Waste heat recovery applications utilise heat pumps to upgrade low-grade waste heat from manufacturing processes, enabling utilisation of otherwise wasted thermal energy for space heating, domestic hot water, or preheating applications. This integration can achieve overall system efficiencies exceeding conventional heating methods while reducing total energy consumption.

District Heating and Large-Scale Applications

Large-scale heat pump installations serve district heating networks by extracting heat from ambient air, ground sources, or waste heat sources and distributing thermal energy through insulated distribution networks. These systems achieve economies of scale while providing efficient heating for multiple buildings or industrial processes.

Ammonia and CO2 heat pumps enable high-temperature applications and industrial process integration while utilising natural refrigerants with minimal environmental impact. These systems can achieve supply temperatures exceeding 80°C while maintaining high efficiency and regulatory compliance.

Specialised Configurations

- Hybrid Systems: Combining heat pumps with conventional heating for optimised performance and reliability

- Thermal Storage Integration: Coupling heat pumps with thermal mass for demand management and grid services

- Heat Recovery Applications: Utilising waste heat sources to improve overall system efficiency

- Multi-Stage Systems: Cascading heat pumps for high-temperature applications

Sensitive Parameters

Heat pump performance depends critically on ambient temperature conditions that directly affect both heating capacity and coefficient of performance. Air-source heat pumps experience significant performance variation with outdoor temperature, with both capacity and efficiency decreasing as ambient temperatures drop. This relationship is non-linear, with performance degrading rapidly at temperatures below the unit's balance point.

Refrigerant charge levels and system cleanliness directly impact heat pump performance and reliability. Refrigerant leaks, dirty coils, or restricted airflow can cause substantial performance degradation and increased energy consumption. The complex refrigerant circuits in heat pumps require specialised service and regular maintenance to maintain design performance.

Load cycling patterns and capacity matching critically affect heat pump efficiency and longevity. Heat pumps achieve optimal efficiency when operating continuously at moderate capacity rather than cycling on and off frequently. Proper sizing and modulation capabilities are essential for maintaining high seasonal performance factors while ensuring adequate heating capacity during design conditions.

Thermal distribution system design significantly influences overall heat pump system performance. Heat pumps achieve highest efficiency with low-temperature distribution systems such as underfloor heating or oversized radiators. High supply temperature requirements for domestic hot water or existing radiator systems can substantially reduce heat pump efficiency and increase operating costs.

Economic Sensitivities

- Electricity Price Volatility: Heat pump operating costs directly correlate with electricity rates and tariff structures

- Time-of-Use Rates: Demand charges and peak pricing significantly impact heat pump operational economics

- Maintenance Cost Escalation: Specialized refrigeration service requirements and component replacement costs

- Refrigerant Regulations: Phase-out schedules and replacement costs for regulated refrigerants

Technical Risk Factors

- Ambient Temperature Dependence: Performance varies significantly with outdoor conditions during peak heating demand

- Refrigerant System Complexity: Leak detection, service requirements, and regulatory compliance challenges

- Electrical Supply Requirements: High electrical loads may require electrical system upgrades

- Integration Complexity: Proper design of thermal distribution systems critical for efficiency

Regulatory and Environmental Considerations

- Refrigerant Regulations: Global warming potential limits and phase-out schedules for synthetic refrigerants

- Efficiency Standards: Minimum performance requirements and energy labeling for heat pump equipment

- Installation Standards: Electrical safety, refrigerant handling, and noise regulations

- Environmental Incentives: Utility rebates and government incentives for high-efficiency heat pump installations

Operational Challenges

- Defrost Cycles: Air-source units require regular defrost operation that temporarily reduces efficiency

- Low-Temperature Performance: Capacity and efficiency degradation during extreme cold weather conditions

- Noise Considerations: Outdoor unit operation may require noise mitigation in residential applications

- Backup Heating: Auxiliary heating requirements during extreme weather or maintenance periods

Performance Optimisation

Efficiency Improvements

Modern heat pump installations benefit from several efficiency enhancement strategies. Variable-speed drive technology enables precise capacity modulation and improved part-load efficiency by matching heating output to demand. These systems avoid the cycling losses associated with fixed-capacity equipment while providing better temperature control and comfort.

Advanced defrost control systems minimise the energy impact of defrost cycles through intelligent algorithms that optimise defrost timing based on actual conditions rather than time-based schedules. Demand defrost and reverse-cycle defrost systems reduce energy consumption while maintaining reliable operation in humid, freezing conditions.

Low-ambient temperature heat pumps extend the operating range and maintain capacity at outdoor temperatures where conventional units lose significant performance. Enhanced vapor injection, two-stage compression, and advanced refrigerant circuits enable reliable operation at temperatures below -20°C while maintaining acceptable efficiency levels.

Integration Strategies

Thermal storage systems enable heat pumps to operate during optimal efficiency periods while providing heating capacity during peak demand or when outdoor conditions are less favorable. Buffer tanks and thermal mass systems reduce cycling frequency while enabling operation during off-peak utility rate periods.

Hybrid systems combine heat pumps with conventional heating to optimise both efficiency and operating costs across varying conditions. These systems automatically switch between heat pump and auxiliary heating based on outdoor temperature, utility rates, or system capacity requirements.

Building management system integration enables comprehensive optimisation through coordinated control of heat pumps, thermal storage, and building loads. Smart controls can implement pre-heating strategies, demand limiting, and load-shifting to minimise operating costs while maintaining comfort requirements.

Conclusion

The Heat Pump module provides essential capabilities for modelling high-efficiency heating systems across diverse applications from residential comfort heating to large-scale industrial process requirements. Understanding the critical parameters affecting heat pump performance, efficiency, and reliability enables informed decision-making about heating system investments and operational strategies.

Successful heat pump installations require careful attention to proper sizing, thermal distribution design, and control strategies that maximise coefficient of performance while ensuring adequate heating capacity during design conditions. The module's comprehensive modelling capabilities enable accurate assessment of different heat pump technologies and configurations for specific application requirements.

Regular monitoring of performance parameters, proactive maintenance scheduling, and continuous optimisation of control strategies ensure heat pump systems deliver reliable, efficient heating throughout their operational life while supporting building electrification and renewable energy integration objectives.