Appearance

Boiler Module

Module Overview

The Boiler module in Encast provides comprehensive modelling capabilities for combustion and electricity-based heating systems designed to generate thermal energy for space heating, domestic hot water production, and industrial process applications. This module enables accurate simulation of various boiler technologies from residential condensing boilers to large-scale industrial steam generation systems across diverse operational configurations.

Boilers represent one of the most established and reliable thermal generation technologies, converting chemical or electrical energy from fuels into thermal energy through controlled combustion processes. The module accounts for various efficiency characteristics and operational constraints to provide accurate performance predictions and economic analysis throughout the system's operational life.

Modern boiler technology encompasses high-efficiency condensing designs that recover latent heat from flue gases, achieving seasonal efficiencies exceeding 95%, alongside traditional non-condensing systems for specific applications. The fuel flexibility, from natural gas and heating oil to biomass and biogas integration, makes boiler systems essential components in comprehensive heating strategies across residential, commercial, and industrial applications.

Data Entry

Installation

Boilers are added by selecting "Create new boiler installation".

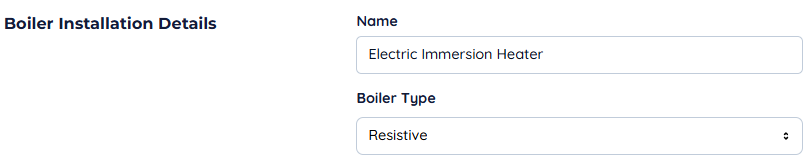

Installation Details

Name: Identifier for the installation. Boiler Type: Boiler, resistive.

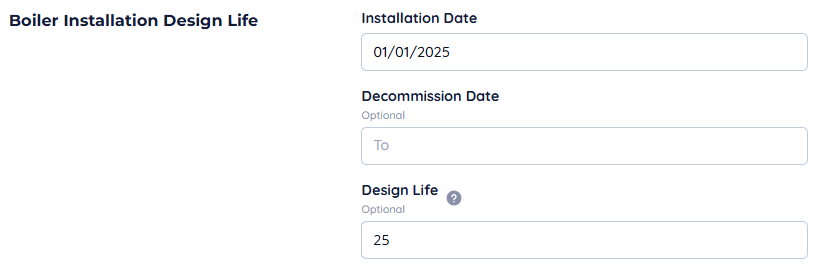

Installation Design Life

Defines the operational period of the boiler.

- Installation Date: Date installation is complete.

- Decommission date (Optional): Date after which the installation is unavailable.

- Design Life (Optional): Number of years from installation date the installation will be available.

An installation date is required. If neither decommission date nor design life are present, the boiler is considered installed until the end of the simulation.

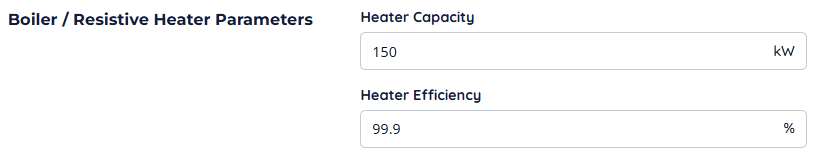

Boiler Specifications

- Boiler Capacity: This is the maximum capacity of the boiler.

- Boiler Efficiency: This is the thermal efficiency of the heater.

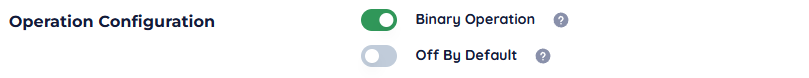

Operation Configuration

- Binary Operation: Set this on to force the boiler to either be entirely on at maximum output or off, this is instead of the default behaviour where output tries to match demand.

- Off By Default: Toggle this to set the installation off until forced on by a criterion, useful for backup heaters for support hotwells.

Operational Times and Maintenance

- Operational Times can be used to define the times when an installation is active.

- Maintenance is used to create shutdown periods to maintain assets or automatic costs based on the number of hours an installation has run.

These are explained in more detail in the Operational Times and Maintenance Section after Modules.

Specialisations and Use Cases

Integration with Other Systems

Boilers complement comprehensive heating systems and support energy security strategies by:

- Providing reliable baseload thermal energy for consistent heating and hot water demands

- Supporting renewable heating systems during peak demand periods or equipment outages

- Enabling district heating networks with centralised thermal generation and distribution

- Integrating with thermal storage systems for demand management and efficiency optimisation

Residential and Commercial Applications

Residential boiler installations represent the backbone of heating systems across diverse climates and building types. Modern condensing boilers achieve exceptional efficiency through recovering latent heat from flue gas condensation, providing both space heating and domestic hot water through combination boiler designs or system boiler configurations with separate hot water cylinders.

Commercial buildings leverage boiler systems for space conditioning, domestic hot water provision, and specialised process requirements. Large commercial installations often incorporate multiple boiler configurations that provide operational redundancy and improved part-load efficiency through staged operation. The modular approach enables capacity matching across varying seasonal demand patterns while maintaining system reliability.

Educational institutions and healthcare facilities utilise boiler systems for critical heating applications where reliability and precise temperature control are essential. These installations often incorporate backup boiler capacity and sophisticated control systems to ensure continuous heating availability for occupant comfort and operational requirements.

Hospitality applications, including hotels and restaurants, require boiler systems capable of handling significant domestic hot water demands alongside space heating requirements. These installations often feature high-capacity systems with thermal storage integration to manage peak hot water usage patterns efficiently.

Industrial Process Applications

Industrial facilities utilise boilers for diverse process heating requirements ranging from low-pressure hot water systems to high-pressure steam generation for manufacturing processes. Steam boilers serve critical roles in food processing, pharmaceutical manufacturing, chemical production, and textile operations where process steam provides heating, sterilisation, and power requirements.

Manufacturing operations leverage industrial boilers for space conditioning in large facilities, process heating for production operations, and cleaning applications requiring high-temperature water or steam. The integration with heat recovery systems enables overall energy efficiency improvements by capturing waste heat from production processes for boiler feed water preheating.

Laundry and dry-cleaning operations depend on steam boilers for garment processing, equipment operation, and facility heating. These applications require consistent steam quality and pressure for effective cleaning and pressing operations while managing significant thermal loads throughout operating periods.

Food processing facilities utilise boilers for cooking processes, sterilisation requirements, cleaning operations, and facility heating. The strict hygiene requirements and food safety regulations necessitate high-quality steam generation with precise temperature and pressure control capabilities.

District Heating and Large-Scale Applications

District heating systems leverage large-scale boiler installations to provide thermal energy for multiple buildings through insulated distribution networks. These systems achieve economies of scale through centralised boiler plants with high-efficiency equipment and professional operation and maintenance capabilities.

Combined heat and power integration enables simultaneous electricity generation and thermal supply through steam turbine or organic Rankine cycle systems. The waste heat recovery from power generation provides high-efficiency thermal supply while generating valuable electricity output.

Specialised Configurations

- Biomass Integration: Boilers designed for renewable solid fuel combustion with automated feed systems

- CHP Integration: Steam boilers supporting combined heat and power generation systems

- Thermal Storage Coupling: Integration with thermal mass systems for demand management

- Multi-Fuel Capability: Boilers capable of operating on multiple fuel types for supply security

Sensitive Parameters

Boiler performance and reliability depend critically on fuel quality and composition parameters that can significantly affect combustion efficiency, emissions compliance, and maintenance requirements. Natural gas composition variations, particularly heating value and Wobbe index, directly impact boiler capacity and efficiency characteristics. Heating oil quality factors, including sulfur content and ash content, affect both combustion performance and maintenance frequency requirements.

Water quality represents one of the most critical factors affecting boiler longevity and operational efficiency. Poor water treatment leading to scale formation, corrosion, or oxygen attack can cause catastrophic boiler failure and void warranty coverage. Water hardness, pH levels, dissolved oxygen content, and treatment chemical concentrations require continuous monitoring and control to prevent operational problems and extend equipment life.

Combustion air quality and temperature significantly affect boiler efficiency and emissions performance. Ambient air temperature variations impact combustion efficiency and flue gas condensation potential in condensing boilers. Dust and contaminant levels in combustion air can cause fouling of heat transfer surfaces and increase maintenance requirements, particularly in industrial environments.

Load cycling patterns critically affect boiler efficiency and equipment longevity. Frequent cycling reduces overall efficiency through heat loss during startup and shutdown periods while increasing mechanical wear on burner components and control systems. The relationship between building heating demand patterns and boiler capacity sizing directly impacts both fuel efficiency and maintenance costs.

Economic Sensitivities

- Fuel Price Volatility: Natural gas and heating oil costs can vary significantly, affecting operational economics

- Efficiency Degradation: Heat exchanger fouling and combustion system wear reduce efficiency over time

- Maintenance Cost Escalation: Specialized service requirements and component replacement affect long-term costs

- Emission Compliance Costs: Environmental regulations may require additional equipment or operational changes

Technical Risk Factors

- Water Quality Issues: Poor water treatment can cause rapid boiler deterioration and failure

- Fuel Supply Reliability: Natural gas supply interruptions or heating oil delivery constraints affect availability

- Combustion System Complexity: Advanced low-NOx burners require specialized maintenance and tuning

- Control System Integration: Poor integration with building management systems reduces efficiency and reliability

Regulatory and Environmental Considerations

- Emission Standards: NOx, CO, and particulate matter limits vary by jurisdiction and installation size

- Efficiency Regulations: Minimum efficiency requirements for new installations and replacement systems

- Safety Regulations: Pressure vessel codes and safety system requirements for steam boilers

- Environmental Permits: Air quality permits and emission monitoring requirements for large installations

Operational Challenges

- Seasonal Efficiency Variation: Condensing boiler performance varies significantly with return water temperatures

- Part-Load Performance: Boiler efficiency typically decreases at low load conditions

- Thermal Shock: Rapid temperature changes can cause stress and premature failure of heat exchangers

- Corrosion Management: Flue gas condensation in non-condensing boilers can cause premature failure

Performance Optimisation

Efficiency Improvements

Modern boiler installations benefit from several efficiency enhancement strategies. Condensing boiler technology recovers latent heat from flue gases when return water temperatures remain below approximately 55°C, achieving seasonal efficiencies exceeding 95%. However, this performance benefit requires careful system design to maintain low return temperatures throughout the heating season.

Boiler sequencing and staging controls optimise multiple boiler installations by operating the minimum number of units required to meet thermal demand while maintaining each unit within its most efficient operating range. Lead-lag control strategies rotate primary and backup boilers to equalise operating hours and maintenance requirements across the installation.

Variable speed combustion air fans and pumps reduce electrical consumption while providing precise control over combustion conditions and thermal output. These systems adapt automatically to varying load conditions while maintaining optimal fuel-air ratios and system efficiency.

Integration Strategies

Thermal storage integration enables boiler systems to operate at higher capacity factors while meeting variable heating demands. Buffer tanks and thermal mass systems reduce boiler cycling frequency while providing thermal energy during peak demand periods that exceed boiler capacity.

Heat recovery systems capture waste heat from flue gases, process equipment, or other thermal sources to preheat boiler feed water or combustion air. Economisers and air preheaters can improve overall system efficiency by 5-15% depending on application conditions and system design.

Building management system integration enables optimised boiler operation based on outdoor temperature, occupancy schedules, and demand forecasting. These systems prevent unnecessary boiler operation while ensuring adequate heating capacity during occupancy periods.

Conclusion

The Boiler module provides essential capabilities for modelling thermal generation systems across diverse applications from residential heating to large-scale industrial process requirements. Understanding the critical parameters affecting boiler performance, efficiency, and reliability enables informed decision-making about heating system investments and operational strategies.

Successful boiler installations require careful attention to fuel quality, water treatment, system integration, and control strategies that optimise both efficiency and reliability. The module's comprehensive modelling capabilities enable accurate assessment of different boiler technologies and configurations for specific application requirements.

Regular monitoring of performance parameters, proactive maintenance scheduling, and continuous optimisation of control strategies ensure boiler systems deliver reliable, efficient thermal energy throughout their operational life while minimising environmental impact and operational costs.